- Back |

- HOME

- / NEWS

- / Technology

- / The working principle and application of 3D optical surface profilometers

The working principle and application of 3D optical surface profilometers

Why is it necessary to measure the surface topography?

In production, the microscopic surface morphology has a direct impact on the evaluation of many technical properties of engineering parts. Moreover, the three-dimensional surface assessment parameters are receiving increasing attention as they can comprehensively and truly reflect the characteristics of the part surface and measure the surface quality. Therefore, the measurement of the three-dimensional microscopic surface morphology is of great significance. By measuring the three-dimensional topography, the quality of the surface can be comprehensively evaluated, and then the effectiveness of the processing method and the rationality of the design requirements can be confirmed. In this way, it can be turned around to guide the processing and optimize the processing technology to produce a high-quality surface, ensuring the realization of the part's functional use.

The measurement principle of the 3D optical surface profilometer

The light emitted by the light source, after being expanded and collimated, is split into two beams by a beam splitter prism. One beam is reflected back by the surface to be measured, while the other beam is reflected by the reference mirror. The two reflected beams converge and interfere with each other. The microscope converts the morphological features of the surface to be measured into interference fringe signals, and the three-dimensional morphology of the surface is measured by measuring the changes in the interference fringes.

The Application of 3D Optical Surface Profilometer

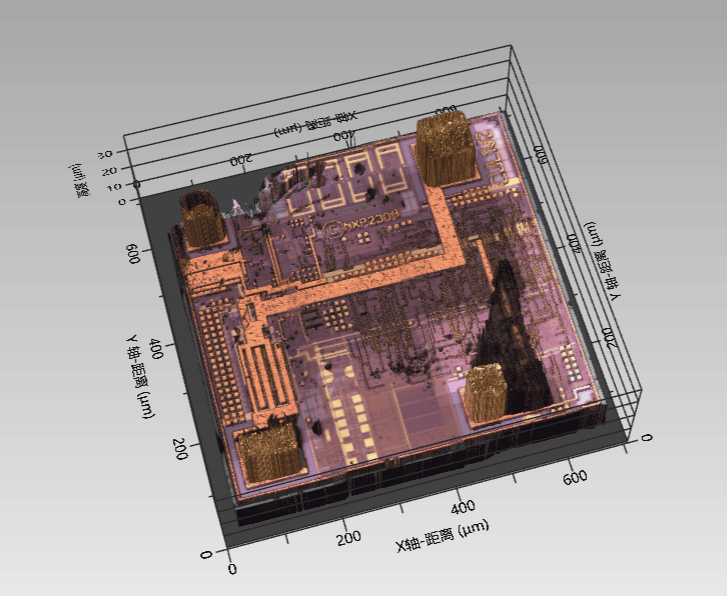

The Profilm3D optical profilometer provided by Unicon Technology Co., Ltd. is suitable for measuring and analyzing surface topography features such as flatness, roughness, waviness, surface profile, surface defects, wear conditions, corrosion conditions, pore gaps, step heights, bending deformation conditions, and processing conditions of various products, components, and materials.